尼龙扎带模具

电缆扎带腔的布局非常类似于一片长叶子,每片叶子都附着在中心树枝“树和树枝”上

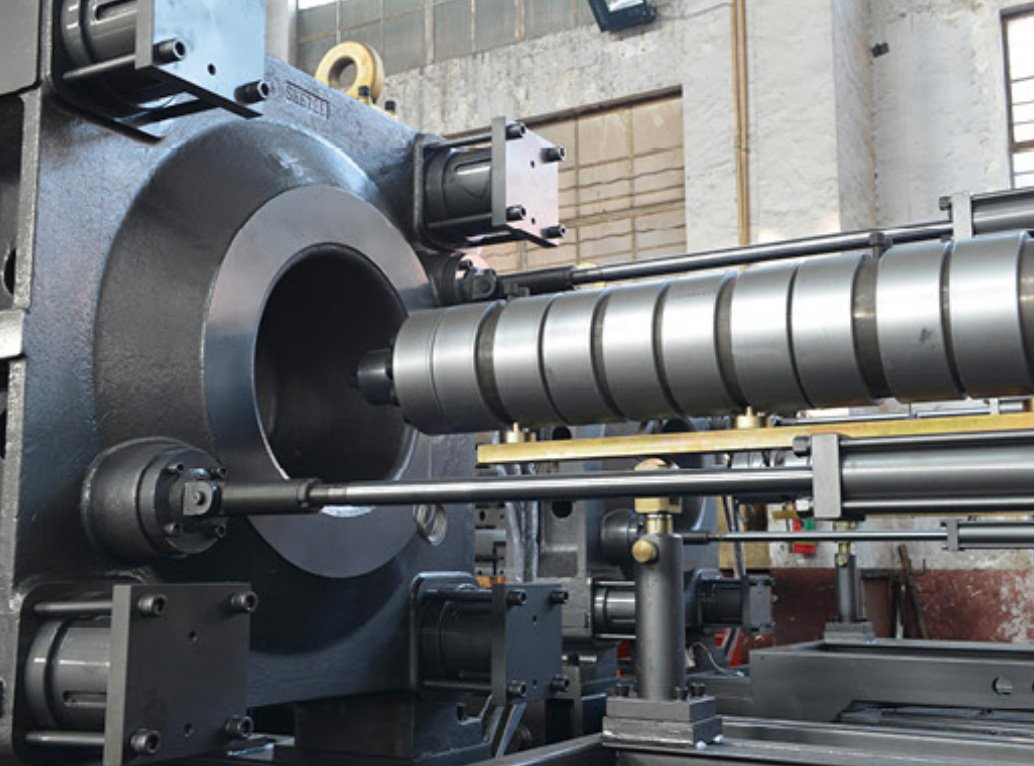

熔融塑料(PA66/PA6)来源于注塑机的喷嘴、浇口、主流道和副流道。随后,它穿过空腔门,到达电缆扎带尾部的末端。这条路的大部分是狭窄平坦的,有许多洞穴。

PA66/PA6被加热到约260℃的高温。当它穿过这条路径时,温度逐渐降低,导致熔体固化。这进一步增强了对熔融塑料前进的阻力。

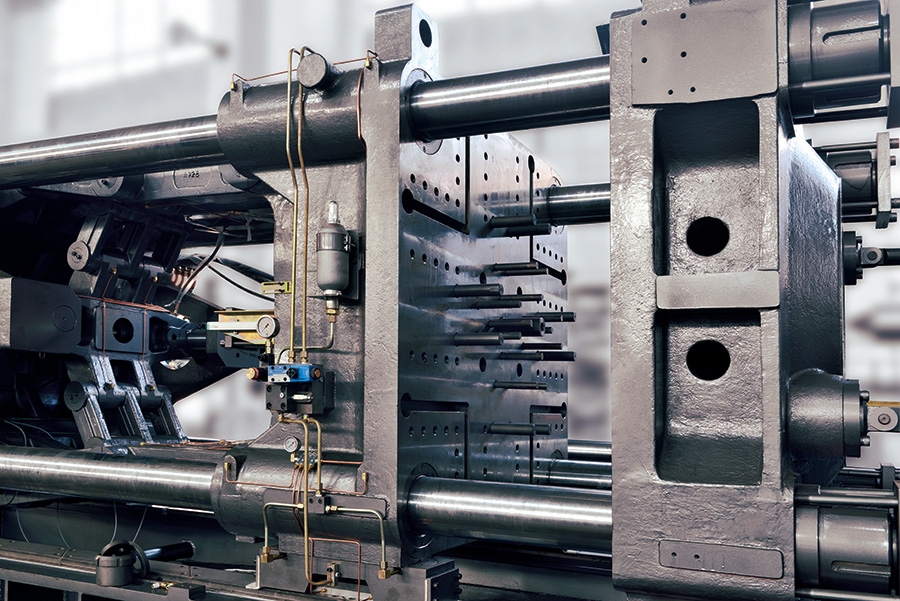

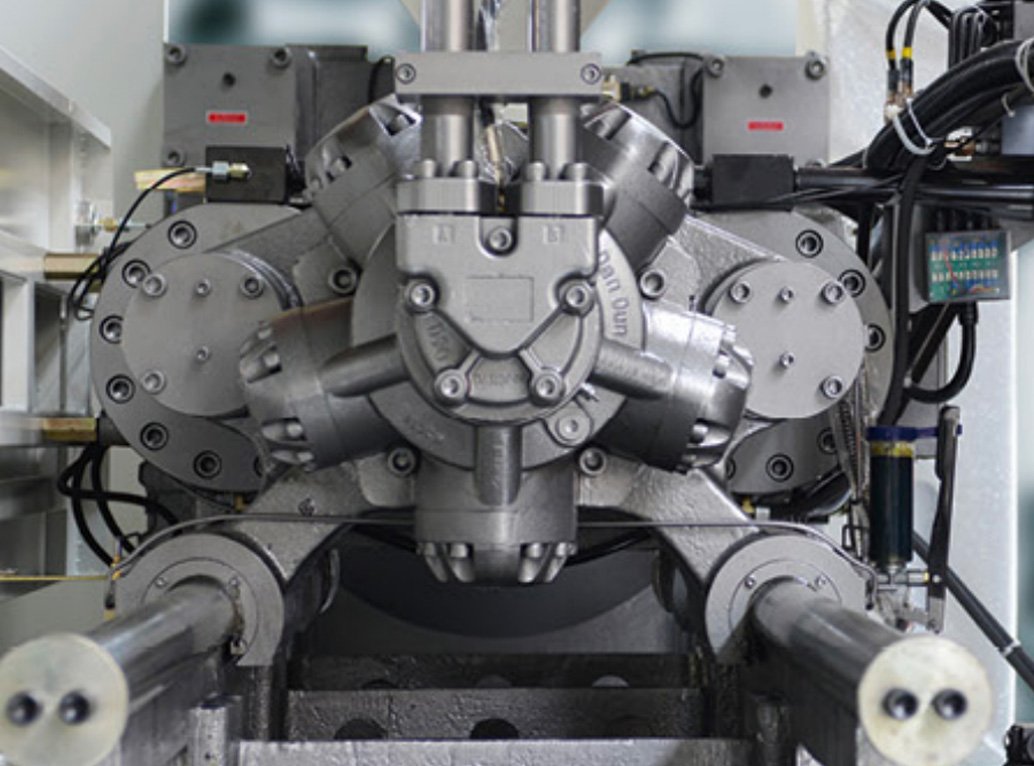

因此,模具温度是模具制造商和操作员必须考虑的首要因素。然而,由于随着时间的推移积累的热量,冷却水转轮也是必要的。

每个腔室都需要一个喷射器,但密集的喷射器会破坏冷却水流道的布局。扎带有各种类型(不同尺寸和设计),模具也是如此。

保持合理的模具成本以避免增加扎带的成本至关重要。特别重要的是扎带的齿和头腔的质量,因为它们是关键部件。

齿应完好无损,没有任何缺失的零件,头腔上部的内表面不应出现任何台阶状的模具偏差。

高质量的尼龙扎带应透明且具有视觉吸引力。

虽然轻微的泛黄是可以接受的,但它们不应该是不透明或深色的.

塑料的分子结构经历了反复的高温熔融剪切作用,这在PA66中更为明显,因为它具有出色的耐磨性和抗拉强度。

给出了一般尺寸和合适的机器型号建议供参考

| 扎带尺寸 | 长 mm | 宽度 mm | 厚度 mm | 腔 | 合适的机型 |

| 3*60 | 60 | 2.4 | 0.9 | 136 | 238T |

| 3*80 | 80 | 2.4 | 1 | 120 | 238T |

| 3*100 | 100 | 2.4 | 1 | 120 | 238T |

| 3*120 | 120 | 2.4 | 1.05 | 100 | 238T |

| 3*150 | 150 | 2.4 | 1.1 | 80 | 238T |

| 3*200 | 200 | 2.4 | 1.15 | 68 | 238T |

| 4*150 | 150 | 3.6 | 1.1 | 68 | 328T |

| 4*180 | 180 | 3.6 | 1.2 | 60 | 328T |

| 4*200 | 200 | 3.6 | 1.25 | 52 | 328T |

| 4*250 | 250 | 3.6 | 1.3 | 40 | 328T |

| 4*280 | 280 | 3.6 | 1.3 | 32 | 328T |

| 4*300 | 300 | 3.6 | 1.3 | 32 | 328T |

| 4*370 | 370 | 3.6 | 1.35 | 24 | 328T |

| 5*180 | 180 | 4.6 | 1.2 | 52 | 328T |

| 5*200 | 200 | 4.6 | 1.25 | 48 | 328T |

| 5*250 | 250 | 4.6 | 1.3 | 32 | 328T |

| 5*280 | 280 | 4.6 | 1.3 | 32 | 328T |

| 5*300 | 300 | 4.6 | 1.35 | 30 | 328T |

| 5*350 | 350 | 4.6 | 1.35 | 28 | 328T |

| 5*380 | 380 | 4.6 | 1.4 | 28 | 328T |

| 5*400 | 400 | 4.6 | 1.4 | 28 | 328T |

| 5*450 | 450 | 4.6 | 1.45 | 16 | 328T |

| 5*500 | 500 | 4.6 | 1.45 | 14 | 328T |

| 8*200 | 200 | 7.2 | 1.25 | 32 | 328T |

| 8*250 | 250 | 7.2 | 1.3 | 28 | 328T |

| 8*300 | 300 | 7.2 | 1.3 | 28 | 328T |

| 8*350 | 350 | 7.2 | 1.35 | 20 | 328T |

| 8*380 | 380 | 7.2 | 1.4 | 16 | 328T |

| 8*400 | 400 | 7.2 | 1.45 | 16 | 328T |

| 8*450 | 450 | 7.2 | 1.45 | 12 | 328T |

| 8*500 | 500 | 7.2 | 1.5 | 12 | 328T |

| 8*550 | 550 | 7.2 | 1.5 | 10 | 328T |

| 10*500 | 500 | 9 | 1.5 | 8 | 328T |

| 10*550 | 550 | 9 | 1.6 | 6 | 328T |

| 10*600 | 600 | 9 | 1.6 | 6 | 328T |

| 10*650 | 650 | 9 | 1.6 | 4 | 328T |

| 10*700 | 700 | 9 | 1.7 | 4 | 328T |

| 10*750 | 750 | 9 | 1.7 | 4 | 328T |

| 10*800 | 800 | 9 | 1.7 | 4 | 328T |

| 10*850 | 850 | 9 | 1.8 | 4 | 328T |

| 10*900 | 900 | 9 | 1.8 | 2 | 328T |

| 10*1000 | 1000 | 9 | 1.8 | 2 | 328T |

| 10*1100 | 1100 | 9 | 2 | 2 | 328T |

| 10*1200 | 1200 | 9 | 2 | 2 | 328T |